Product Center

DPP-150 Aluminum Plastic Packaging Machine

Category:

Product accessories:

Key words:

Product Description

Features:

The new domestic transmission mechanism is adopted, and the main transmission shaft is driven by the platoon chain, which eliminates the error and noise of other gear transmission.

The electrical appliance adopts an imported control system, and it can be equipped with a missing material and leakage compensation device and a missing particle detection and removal device according to customer requirements.

The use of photoelectric control system, automatic feeding of PVC, PTP, hard aluminum packaging, and automatic punching of waste edges ensure the stability of ultra-long distance multi-station synchronization.

It can be equipped with photoelectric detection and correction device, with imported stepping motor traction, graphic and text-to-plate printing and packaging, to optimize the grade of packaging.

This machine is suitable for industries: food, medicine, medical equipment, hardware, electronic blister packaging.

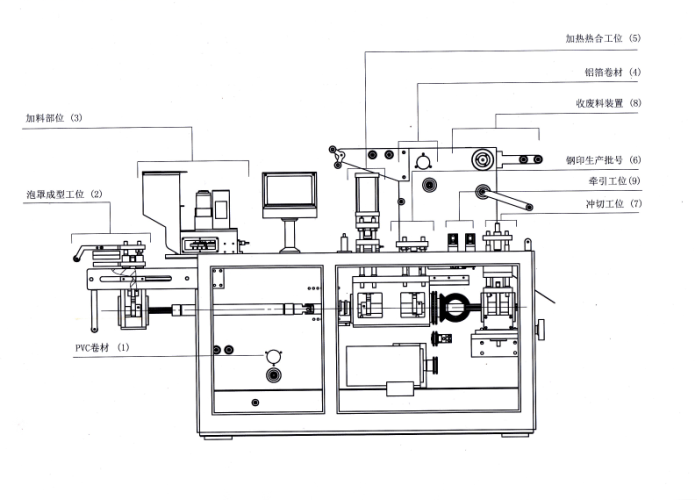

working principle:

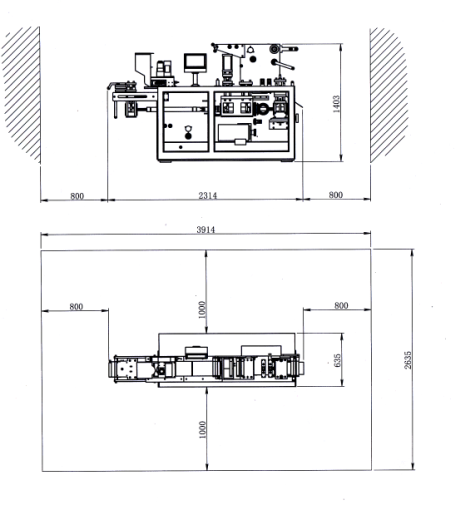

Dimensional layout drawing:

Technical Parameters

|

Cutting times |

10∽35 (times/min) |

|

Production capacity |

1200∽4200 ( |

|

Max forming area and depth |

130×100(standard thickness≤15mm ) maximum depth 26mm |

|

Travel range |

50∽120mm( |

|

Standard Sheet |

80×57mm ( |

|

Clean air |

0.4∽0.6Mpa |

|

Air consumption |

(Air compressor) ≥0.3m3/min |

|

Total Power |

380V 50HZ 3.8kw |

|

Main motor power |

1.5KW |

|

PVC sheet |

(0.15∽0.5)×150mm |

|

PTP aluminum foil |

(0.02∽0.035)×150mm |

|

Dialysis paper |

(0.02∽0.035)×150mm |

|

Mold cooling |

Tap water or recycled water |

|

Dimensions |

2315×635×1405mm (L×W×H) |

|

Machine weight |

820KG |

|

Gross |

890KG |

|

Outside the box size |

2500×800×1780mm (L×W×H) |

|

Noise |

<75 db |

Solution

Solutions for your industry, ready for your choice